The world of CNC (Computer Numerical Control) plasma cutting has evolved dramatically, driven by innovations in electronics, software, and motion control. Whether you’re a hobbyist, a small workshop owner, or an industrial manufacturer, having the right CNC controller and electronics can make the difference between precision cuts and costly errors.

In this article, we will explore four key components that define modern CNC plasma cutting systems:

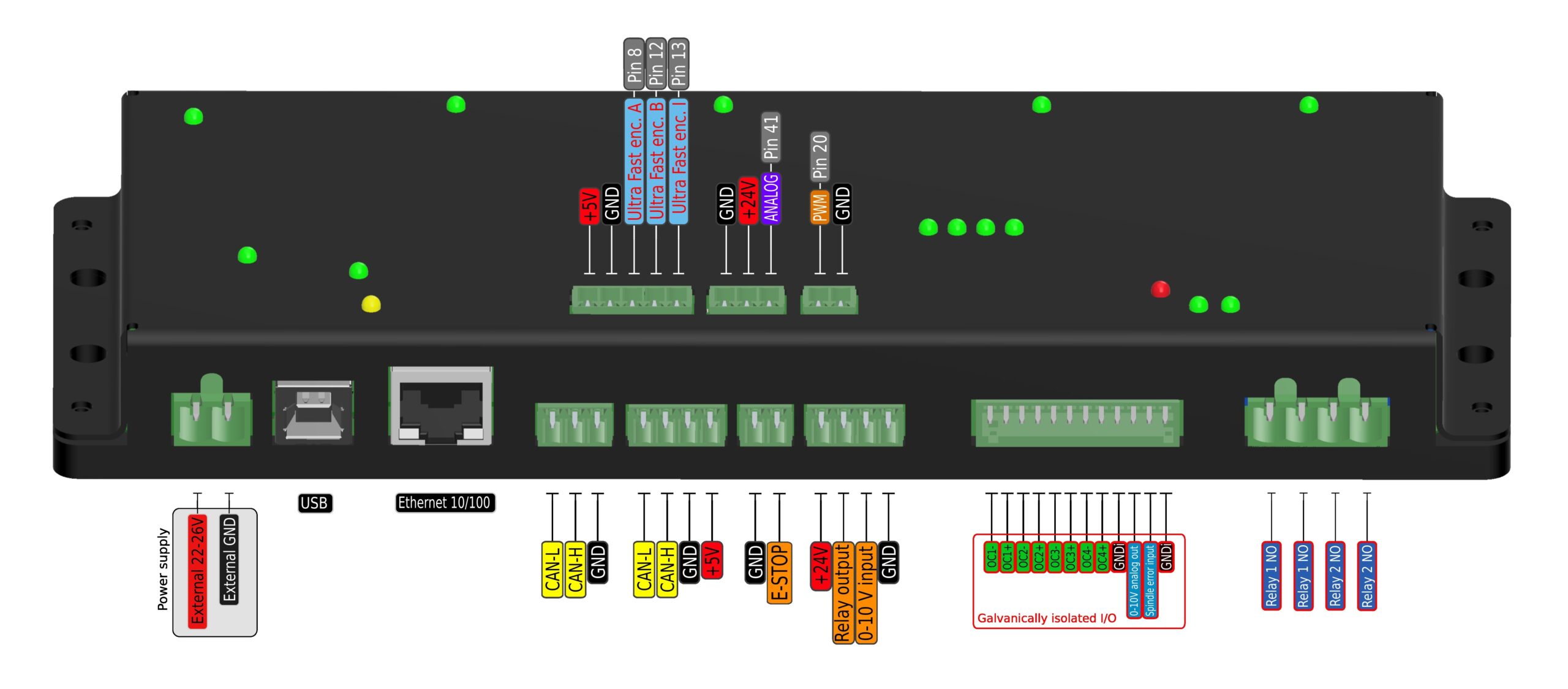

PoKeys57CNCpro4x25 – A versatile motion controller designed for high-performance CNC applications.

CNC controller with drivers – The backbone of any CNC system, integrating motion control and driver compatibility.

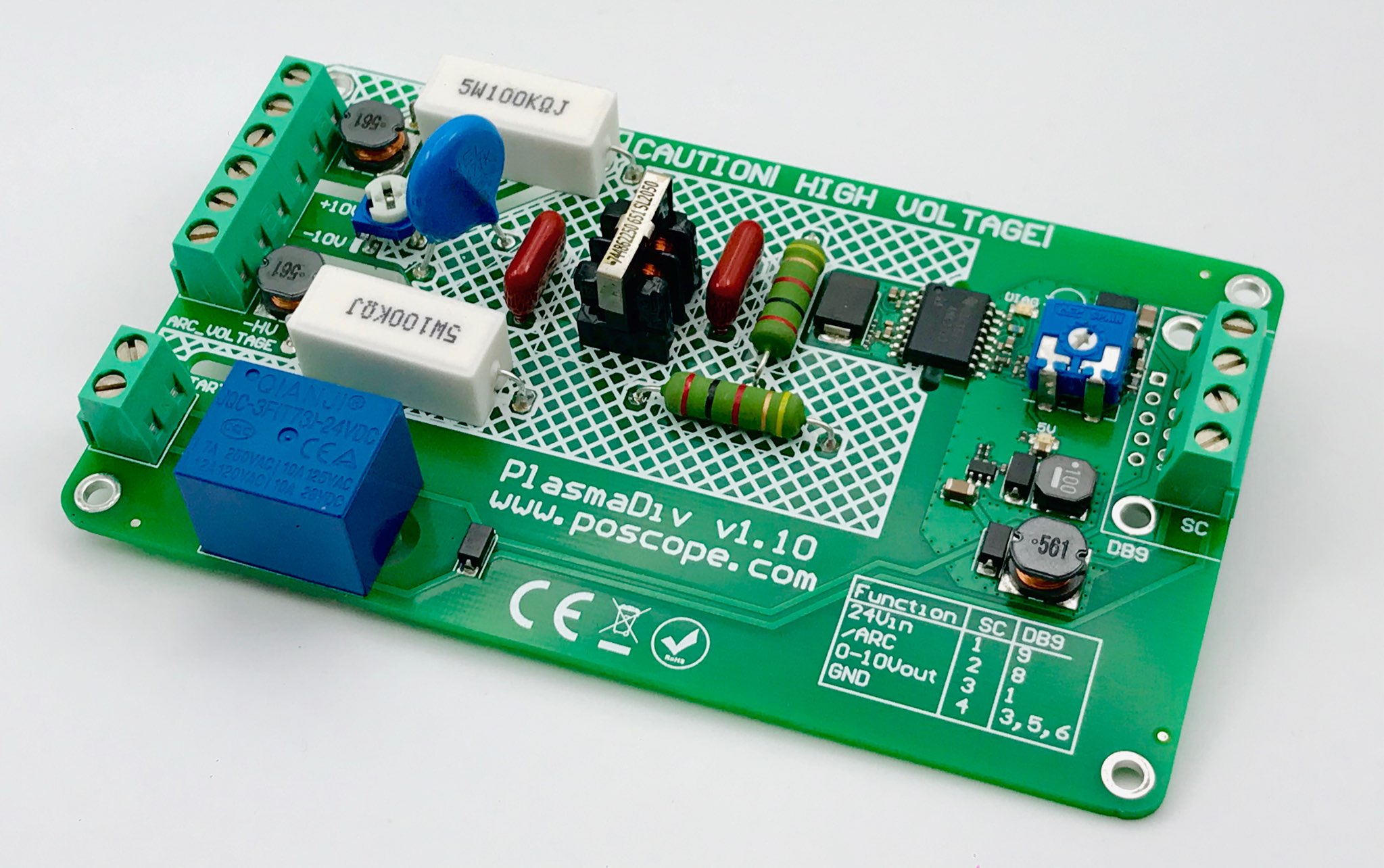

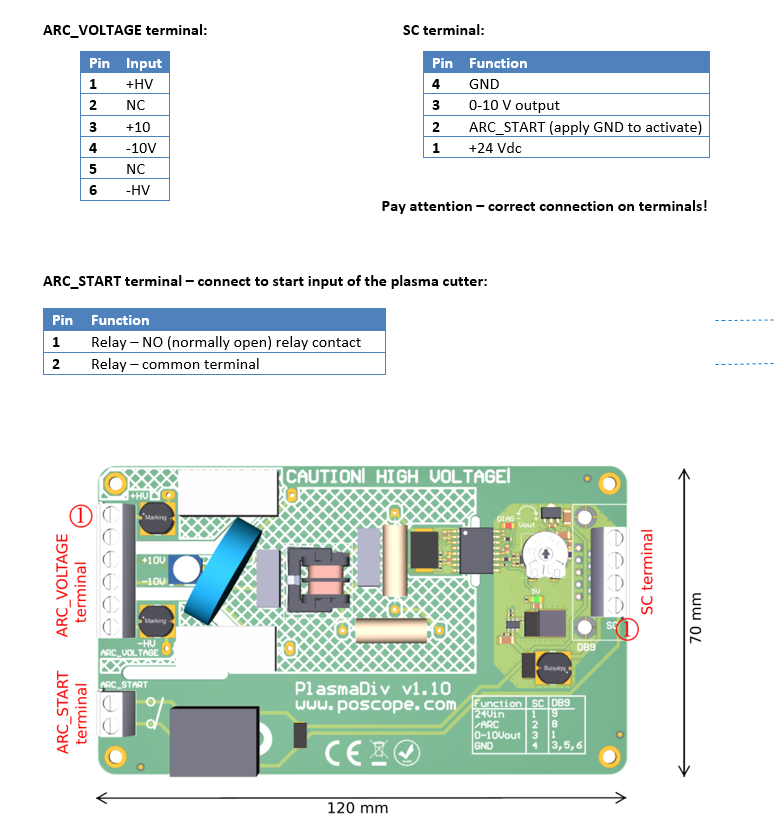

PlasmaDiv – A specialized solution for plasma cutting, ensuring smooth arc control and optimal performance.

CNC plasma electronics – The critical hardware that powers plasma cutters, from power supplies to I/O management.

Each of these elements plays a crucial role in achieving efficient, accurate, and reliable plasma cutting. By understanding their functions and advantages, you can make informed decisions when upgrading or building your CNC plasma system.

Let’s dive into each topic in detail, answering the most pressing questions about these cutting-edge technologies.

The PoKeys57CNCpro4x25: A High-Performance Motion Controller for CNC Plasma Cutting

Precision motion control lies at the heart of efficient CNC plasma cutting, and the PoKeys57CNCpro4x25 has emerged as a powerful solution for demanding applications. This advanced motion controller bridges the gap between software commands and physical machine movements, delivering the responsiveness and accuracy required for clean, consistent plasma cuts.

At its core, the PoKeys57CNCpro4x25 functions as the central nervous system of a CNC plasma setup. Unlike simpler controllers, this device combines multi-axis coordination with extensive input/output capabilities, making it well-suited for both hobbyist workshops and industrial environments. The unit’s four-axis motion control allows simultaneous management of multiple stepper or servo motors, enabling complex cutting paths without sacrificing speed or precision.

One of the standout advantages of the PoKeys57CNCpro4x25 is its real-time processing capability. Plasma cutting often involves rapid directional changes and high-speed movements, where even minor delays can result in irregular cuts or excessive dross. By minimizing command latency, this controller ensures smooth torch movement across all axes, maintaining optimal cut quality even when working with intricate designs or thick materials.

The controller’s versatility extends to its connectivity options. With both Ethernet and USB interfaces, the PoKeys57CNCpro4x25 establishes fast, stable communication with popular CNC software platforms like Mach3, Mach4, and LinuxCNC. This broad compatibility makes it easy to integrate into existing workflows while providing room for future expansions. Additionally, its 25 configurable digital I/O ports offer ample flexibility for connecting sensors, limit switches, and other peripherals essential for automated operation.

When deployed in plasma cutting applications, the PoKeys57CNCpro4x25 truly shines through its integration capabilities. The controller works in perfect harmony with PlasmaDiv systems, ensuring reliable arc ignition and maintaining consistent torch height throughout the cutting process. This synergy between motion control and plasma-specific electronics results in cleaner cuts with reduced bevel and minimal slag formation.

The device also plays well with other critical CNC plasma electronics, including motor drivers and power supplies. When combined with a robust CNC controller with drivers, the PoKeys57CNCpro4x25 forms a complete motion control solution that handles everything from basic straight-line cuts to complex contour following. Its programmable PWM and analog outputs further enhance functionality by allowing precise adjustment of spindle speeds and automatic torch height correction.

For operators seeking to optimize their plasma cutting performance, the PoKeys57CNCpro4x25 offers an ideal balance of power and flexibility. Its ability to process complex movements in real time, coupled with extensive connectivity options, makes it equally valuable for small-scale fabrication and high-volume production environments. As we’ll explore next, pairing this capable motion controller with the right CNC controller with drivers can further streamline operations and improve overall cutting efficiency.

CNC Controller with Drivers: The Command Center for Precision Plasma Cutting

Behind every high-performance CNC plasma cutter lies a critical component that orchestrates the entire operation—the CNC controller with drivers. This integrated system serves as the central command hub, translating digital designs into precise physical movements while managing the complex interplay between motors, sensors, and cutting tools.

The Synergy of Control and Motion

A modern CNC controller with drivers combines two essential functions into a single, streamlined package. The controller itself processes G-code instructions and coordinates machine movements, while the integrated drivers provide the necessary power and signals to stepper or servo motors. This unified approach eliminates compatibility issues between separate components and creates a more responsive, reliable system.

Unlike standalone controllers that require external driver modules, an integrated CNC controller with drivers offers several distinct advantages for plasma cutting applications. The direct coupling between control logic and motor output results in faster signal processing, which is crucial when executing the rapid directional changes common in plasma cutting. Additionally, the unified design typically includes optimized current control for smoother motor operation, reducing vibration and improving cut quality.

Precision Engineering for Plasma Applications

Plasma cutting presents unique challenges that demand specialized control capabilities. A high-quality CNC controller with drivers addresses these through features like advanced arc voltage monitoring and real-time torch height adjustment. These systems maintain optimal cutting conditions by dynamically responding to changes in material thickness or surface irregularities, ensuring consistent cut quality across the entire workpiece.

The integration of drivers within the controller also enhances system reliability. With fewer external connections and cables, there’s reduced risk of signal interference or connection failures that could disrupt production. Many modern units include built-in protection circuits that safeguard against voltage spikes, overheating, and other common electrical issues that could damage sensitive CNC plasma electronics.

Scalability and Customization Options

One of the most significant benefits of contemporary CNC controller with drivers solutions is their modular design. Operators can typically expand systems to accommodate additional axes or integrate specialized peripherals like rotary attachments. This scalability makes the same controller suitable for everything from simple 2-axis cutting tables to complex 3D plasma profiling systems.

Advanced units often feature programmable I/O ports that allow customization for specific workflow requirements. These might include automated gas control, part detection sensors, or safety interlocks—all controllable directly through the same interface that manages motion commands. When paired with components like the PoKeys57CNCpro4x25, these systems gain even greater flexibility for specialized plasma cutting applications.

The Future of Integrated Control

As plasma cutting technology advances, CNC controller with drivers systems continue evolving to meet new demands. Modern units increasingly incorporate features like predictive motion algorithms that anticipate and compensate for mechanical system limitations, as well as cloud connectivity for remote monitoring and diagnostics. These developments are creating smarter, more efficient plasma cutting systems that maintain precision while reducing setup times and operator intervention.

The right CNC controller with drivers serves as the foundation for any high-performance plasma cutting operation. By combining precise motion control with robust driver technology, these systems deliver the speed, accuracy, and reliability needed for both production environments and custom fabrication work. In our next section, we’ll examine how specialized components like PlasmaDiv further enhance these capabilities for optimal plasma cutting performance.

PlasmaDiv: The Specialized Brain Behind Precision Plasma Cutting

At the heart of every professional plasma cutting operation lies a critical component that transforms raw power into precision cuts – PlasmaDiv. This specialized control module serves as the intelligent interface between your CNC system and plasma power source, managing the complex variables that determine cut quality. Unlike generic CNC controllers, PlasmaDiv is engineered specifically for plasma applications, offering features that address the unique challenges of thermal cutting processes.

The system operates by continuously monitoring and adjusting three key parameters: arc voltage, current flow, and torch height. This real-time optimization ensures consistent cut quality even when working with uneven materials or complex contours. PlasmaDiv‘s advanced algorithms automatically compensate for variations in material thickness, surface conditions, and cutting speed – adjustments that would require constant manual intervention with basic control systems.

Key Advantages in Industrial Applications

PlasmaDiv revolutionizes plasma cutting operations through several technological innovations. Its dynamic height control system maintains optimal torch-to-work distance within ±0.1mm, crucial for achieving clean cuts with minimal bevel. The module’s sophisticated arc starting sequence significantly reduces consumable wear by implementing a soft-start technology that gently initiates the plasma arc rather than using a brute-force high-frequency start.

For operations using high-definition plasma systems, PlasmaDiv offers specialized gas control capabilities. It precisely manages pre-flow and post-flow timing, along with gas pressure ramping, to protect expensive consumables and extend their service life. The system’s automatic voltage control (AVC) responds to arc voltage fluctuations within milliseconds, maintaining perfect torch height even when cutting corrugated or painted materials.

Integration with Existing CNC Infrastructure

One of PlasmaDiv‘s most valuable features is its seamless integration with standard CNC components. The module connects directly with popular CNC controller with drivers systems, including those using PoKeys57CNCpro4x25 technology. This compatibility allows shops to upgrade their plasma capabilities without replacing their entire motion control system.

The unit interfaces with all major plasma power sources through standard analog and digital I/O connections. Its modular design accommodates various communication protocols, from basic voltage signals to modern industrial Ethernet standards. For advanced users, PlasmaDiv provides customizable I/O mapping, allowing integration with automated material handling systems, fume extraction controls, and other peripheral devices.

Smart Features for Modern Fabrication

Modern versions of PlasmaDiv incorporate several intelligent features that push plasma cutting into Industry 4.0 territory. The system’s data logging capabilities record cutting parameters for every job, creating a searchable database of optimal settings for different materials and thicknesses. Some models even include predictive maintenance functions that monitor consumable wear rates and alert operators before quality degrades.

When combined with other CNC plasma electronics, PlasmaDiv enables advanced process automation. The system can automatically adjust cutting parameters when it detects material changes through arc voltage signatures or external sensors. For high-mix production environments, this intelligence dramatically reduces setup time and minimizes scrapped parts from incorrect parameter settings.

The Competitive Edge in Metal Fabrication

In today’s competitive manufacturing landscape, PlasmaDiv provides fabricators with measurable advantages. The system typically reduces consumable costs by 20-30% through optimized arc control and reduced failed starts. Its precision height control allows shops to cut thinner materials at higher speeds without warping, while maintaining the ability to handle thick plate when needed.

Perhaps most importantly, PlasmaDiv delivers these benefits while actually simplifying operation. The system’s automatic functions reduce the skill level required to produce quality cuts, allowing less experienced operators to achieve results that previously required seasoned professionals. This combination of performance and usability makes PlasmaDiv an essential component for shops looking to maximize their plasma cutting investment.

CNC Plasma Electronics: The Nervous System of Modern Cutting Systems

Behind every precise plasma cut lies a sophisticated network of CNC plasma electronics that control, monitor, and optimize the entire cutting process. These components form the technological backbone of any plasma cutting system, working in unison to convert digital designs into flawless physical cuts. Unlike standard machining operations, plasma cutting presents unique electrical challenges – from managing extreme temperatures to maintaining arc stability – that demand specialized electronic solutions.

The core of these systems begins with the power supply, which must deliver exceptionally stable current despite fluctuating loads as the torch moves through different material thicknesses. Modern CNC plasma electronics achieve this through advanced inverter technology and real-time feedback loops that adjust output within microseconds. This level of control prevents common issues like arc wandering or excessive dross, particularly when cutting conductive but uneven materials like rusted steel or aluminum.

Precision Control Through Advanced Sensing Technology

What separates professional-grade plasma systems from basic cutters is their network of sensors and control circuits. High-end CNC plasma electronics incorporate multiple monitoring points that track:

- Arc voltage – The primary indicator of cut quality and torch height

- Current flow – Ensuring consistent energy delivery despite material variations

- Gas pressure – Critical for maintaining proper shielding and cut geometry

- Temperature – Protecting components from plasma’s extreme heat

These sensors feed data to the central control system (often incorporating PlasmaDiv technology) which makes hundreds of micro-adjustments per second. This continuous optimization allows modern plasma cutters to maintain tolerances within ±0.2mm even on thin materials moving at several meters per minute.

Integration With Motion Control Systems

The true power of CNC plasma electronics emerges when synchronized with motion control components like the PoKeys57CNCpro4x25. This integration creates a closed-loop system where:

- The CNC controller dictates torch path and speed

- Plasma electronics adjust energy output in real-time

- Height control maintains optimal standoff distance

- All systems continuously communicate to compensate for variables

This synergy is particularly evident when piercing thick materials or navigating complex contours. The electronics anticipate needed power adjustments before the torch reaches challenging sections, preventing common defects like excessive top spatter or incomplete cuts.

Smart Features Redefining Plasma Cutting

Contemporary CNC plasma electronics now incorporate intelligent features that were unimaginable a decade ago:

- Automatic gas selection – Switching between different gases/ratios based on material type

- Predictive maintenance – Monitoring consumable wear and alerting before failures occur

- Adaptive cutting – Adjusting parameters mid-cut when encountering material variations

- Cloud connectivity – Remote monitoring and data collection for process optimization

These advancements are particularly valuable when paired with a high-performance CNC controller with drivers, creating systems that essentially “learn” optimal settings for specific applications over time.

The Future of Plasma Cutting Technology

As CNC plasma electronics continue evolving, we’re seeing three key trends:

- Miniaturization – More powerful components in smaller packages

- Standardization – Universal communication protocols for easier integration

- AI integration – Machine learning algorithms for predictive parameter adjustment

These developments promise to make precision plasma cutting more accessible while pushing the boundaries of what’s possible in terms of cut quality, speed, and material versatility. For fabricators, this means being able to tackle increasingly complex jobs with confidence, knowing their CNC plasma electronics will compensate for real-world variables that used to require constant manual intervention.

The combination of robust hardware and intelligent software in modern plasma systems represents a quantum leap from earlier generations. When every component – from the PoKeys57CNCpro4x25 motion controller to the PlasmaDiv interface – works in perfect harmony through advanced CNC plasma electronics, the result is cutting performance that approaches laser-like precision at plasma’s characteristic speed and cost-efficiency.

IEPE, USB MSOs, and the Rise of Portable Oscilloscopes

Code, Cables, and Orchids: The Unlikely Tools Shaping Modern Creation

The Future of Intelligent Plasma Cutting Systems

The evolution of CNC plasma cutting has reached an exciting inflection point, where advanced components like the PoKeys57CNCpro4x25, integrated CNC controller with drivers, PlasmaDiv modules, and sophisticated CNC plasma electronics are converging to create smarter, more capable systems than ever before. What was once a process requiring constant manual oversight has transformed into a highly automated operation where intelligent systems make real-time adjustments beyond human reaction capabilities.

The synergy between these technologies is reshaping metal fabrication. Motion controllers like the PoKeys57CNCpro4x25 provide the precise movement foundation, while unified CNC controller with drivers solutions ensure perfect synchronization between commands and mechanical action. Specialized PlasmaDiv systems bring plasma-specific intelligence to the equation, optimizing arc characteristics and torch positioning. All these elements are tied together by advanced CNC plasma electronics that monitor dozens of parameters simultaneously, creating a cutting process that continuously self-optimizes.

Looking ahead, we can anticipate several key developments in plasma cutting technology. Machine learning algorithms will likely play a larger role in predictive parameter adjustment, analyzing thousands of successful cuts to determine optimal settings for new materials. Enhanced sensor networks may provide real-time material analysis, automatically detecting surface conditions or alloy variations. Wireless connectivity and cloud-based analytics will enable remote diagnostics and performance benchmarking across multiple machines.

For manufacturers and fabricators, these advancements translate to unprecedented levels of efficiency and quality. The latest generation of plasma systems reduces the skill threshold for operators while simultaneously pushing the boundaries of what’s possible in terms of cut precision and speed. Consumable life extends dramatically thanks to smarter arc control, and the reduction in manual adjustments allows staff to focus on higher-value tasks.

As these technologies continue to mature, we’re witnessing the emergence of plasma cutting systems that combine the precision once exclusive to lasers with the material versatility and cost-effectiveness that made plasma cutting popular. The integration of components like PoKeys57CNCpro4x25, CNC controller with drivers, PlasmaDiv, and advanced CNC plasma electronics represents more than incremental improvement—it’s a fundamental shift toward intelligent, self-optimizing fabrication systems that promise to redefine metal cutting for years to come.

For businesses considering upgrading their plasma capabilities, the message is clear: investing in these integrated, intelligent systems isn’t just about keeping pace with technology—it’s about positioning for the future of manufacturing, where connectivity, automation, and data-driven optimization separate industry leaders from the competition. The cutting edge of plasma technology has arrived, and it’s sharper than ever.