In the rapidly evolving world of electronics and CNC machinery, having the right tools and components is crucial for both hobbyists and professionals. Whether you are building a precision CNC machine, testing intricate circuits, or integrating advanced controllers, understanding the technology behind these tools can significantly enhance performance and efficiency.

This article explores four essential elements that have become increasingly relevant in modern electronics and CNC applications: the PoStep25-256 stepper driver, PCB testers, the PoKeys57CNCpro4x25 controller, and comprehensive CNC controllers with drivers. Each of these components plays a unique role in ensuring smooth operation, precise control, and reliable results, making them indispensable for anyone working in these fields. By examining these topics in detail, this guide aims to provide both foundational knowledge and practical insights, helping readers make informed decisions when selecting or utilizing these technologies.

What is the PoStep25-256 and why is it important in modern CNC applications?

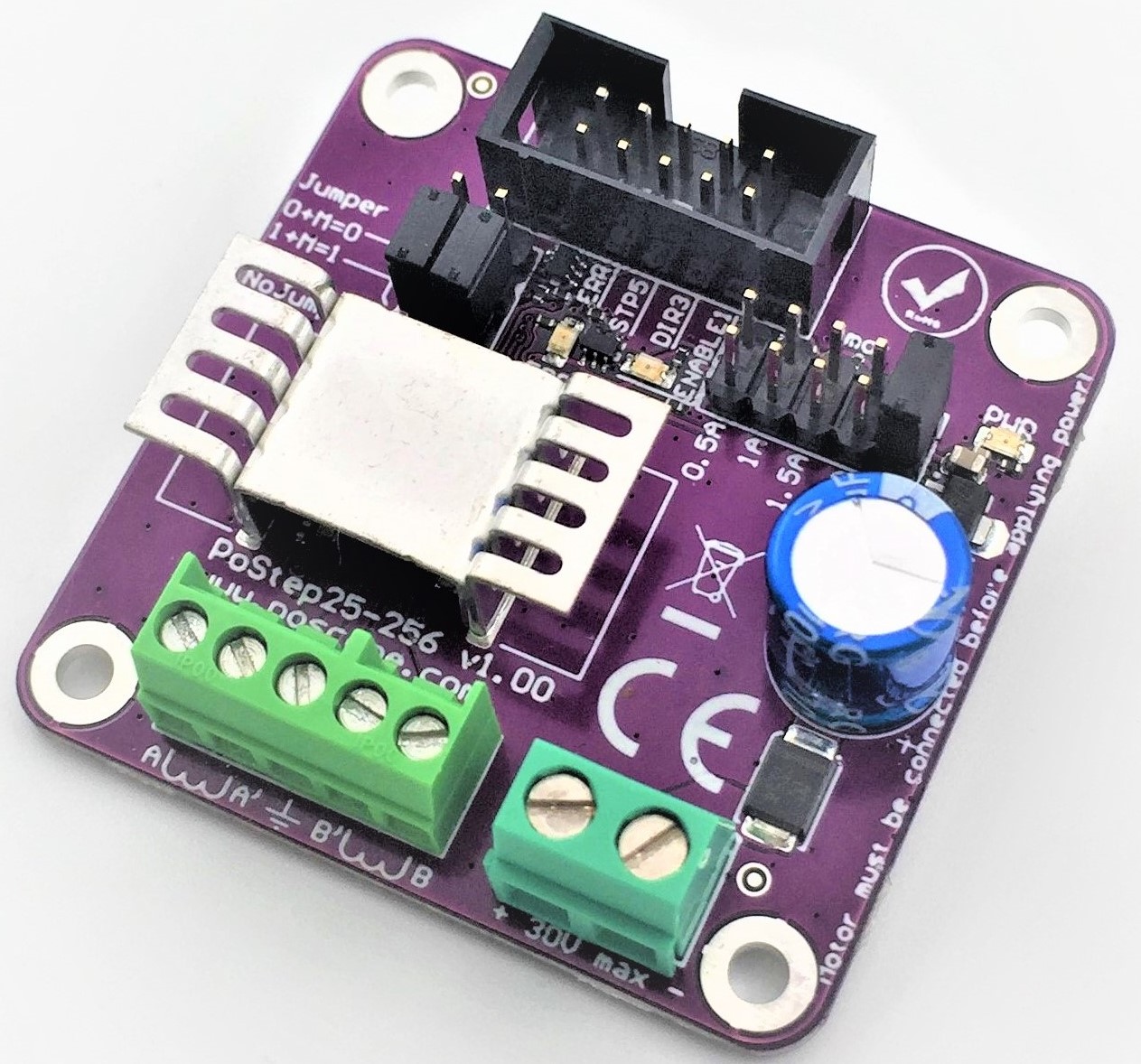

The PoStep25-256 is a high-performance stepper motor driver designed to provide precise and smooth motion control for a wide range of applications, particularly in CNC machinery and robotics. Stepper motors are essential for accurate positioning in these systems, and the PoStep25-256 stands out due to its advanced microstepping capabilities, which allow motors to operate with minimal vibration and high positional accuracy. Unlike traditional drivers, the PoStep25-256 supports up to 256 microsteps per full step, making it ideal for applications where fine control is essential, such as engraving, 3D printing, or milling intricate components.

One of the key advantages of the PoStep25-256 is its flexibility. It can interface with various control systems, including popular CNC controllers, making it a versatile choice for both custom-built machines and retrofitting existing setups. Its robust design ensures reliable operation even under demanding conditions, which is crucial in industrial environments where downtime can be costly. Users often note that the PoStep25-256 provides smoother acceleration and deceleration profiles compared to standard drivers, reducing mechanical stress on the stepper motors and extending their operational life.

In addition to its technical specifications, the PoStep25-256 is appreciated for its ease of configuration. Software interfaces allow operators to adjust parameters such as current limits, microstepping resolution, and decay modes, ensuring that the driver can be finely tuned to match the specific characteristics of the connected stepper motor. This level of control makes the PoStep25-256 particularly popular among hobbyists and professionals who demand precise and repeatable motion in their CNC projects.

Moreover, the PoStep25-256 is often paired with high-end CNC controllers to achieve a fully integrated motion system. By combining the PoStep25-256 with controllers like the PoKeys57CNCpro4x25, users gain the ability to manage multiple axes simultaneously, implement complex motion profiles, and maintain consistent performance across various tasks. Its reliability, precision, and adaptability have made the PoStep25-256 a staple in modern CNC setups, ensuring that machines operate with maximum efficiency and accuracy.

Ultimately, the PoStep25-256 is more than just a stepper motor driver; it is a key component that enables CNC machines and robotic systems to reach their full potential. Its combination of high microstepping resolution, configurability, and robustness makes it an indispensable tool for anyone seeking precision motion control in demanding applications. Whether for a professional workshop or a sophisticated hobby project, the PoStep25-256 consistently delivers performance that meets the highest standards.

More:

– Partners posts

What is a PCB tester and why is it essential for electronics development?

A PCB tester is a specialized tool used to verify the functionality and integrity of printed circuit boards before they are integrated into larger systems. In modern electronics, where circuits are becoming increasingly complex and densely packed, ensuring that a PCB operates correctly is critical. A PCB tester allows engineers and technicians to detect issues such as short circuits, open connections, incorrect component placements, or soldering defects, which could otherwise lead to system failures. By identifying these problems early, PCB testers save time, reduce waste, and prevent costly mistakes in both prototype and production environments.

The importance of a PCB tester lies not only in quality assurance but also in speeding up the development process. When designing new electronics, iterations are frequent, and each new PCB version must be verified for correctness. A reliable PCB tester can quickly provide feedback on whether the board meets design specifications, enabling faster debugging and refinement. Modern PCB testers often include automated testing features that can run a sequence of electrical checks on all critical nodes, giving engineers confidence that every trace and component behaves as intended. This is particularly valuable when working with multilayer boards, where hidden faults are otherwise difficult to detect.

Another critical aspect of PCB testers is their adaptability. Advanced testers can accommodate a wide range of board sizes, layouts, and component types, making them versatile tools for both small-scale projects and large-scale manufacturing. They often integrate with software platforms that allow users to design test sequences, log results, and analyze patterns of faults over time. This level of sophistication turns PCB testers into not just diagnostic tools but also powerful instruments for optimizing design and assembly processes.

PCB testers are also closely linked to precision motion and control systems in some applications. For example, when verifying boards designed for CNC controllers, stepper drivers, or other automation equipment, a PCB tester ensures that all electrical connections correspond accurately to mechanical control requirements. This synergy between PCB testing and systems like PoStep25-256-driven CNC setups or PoKeys57CNCpro4x25 controllers highlights how reliable electronics verification underpins the overall performance of advanced machinery.

In summary, a PCB tester is indispensable in modern electronics because it guarantees that printed circuit boards function correctly, improves development speed, and supports the creation of reliable, high-performance systems. Whether for a small hobbyist project or an industrial production line, PCB testers provide the confidence that every board is built to specification and ready to perform in its intended application.

What is the PoKeys57CNCpro4x25 and how does it enhance CNC control systems?

The PoKeys57CNCpro4x25 is a sophisticated CNC controller designed to manage complex motion tasks with precision, reliability, and flexibility. As CNC machines become more advanced, the demand for controllers that can handle multiple axes, integrate with stepper drivers, and provide real-time monitoring has grown. The PoKeys57CNCpro4x25 meets these demands by combining high-performance hardware with versatile software support, making it a preferred choice for both professional workshops and dedicated hobbyists.

One of the defining features of the PoKeys57CNCpro4x25 is its ability to interface with a wide range of stepper drivers, including the PoStep25-256, allowing users to configure their machines for maximum accuracy and smooth operation. This controller can manage multiple axes simultaneously, executing complex motion paths while maintaining precise timing and synchronization. Its robust architecture ensures that even in demanding applications, the PoKeys57CNCpro4x25 delivers consistent performance, minimizing errors and improving overall machining quality.

The PoKeys57CNCpro4x25 also excels in its configurability. Users can adjust parameters for acceleration, speed, and motion profiles, tailoring the system to specific machines and tasks. It integrates seamlessly with popular CNC software platforms, enabling intuitive control, real-time diagnostics, and automated routines. These features make it easier to implement complex processes, such as simultaneous milling and engraving, without compromising accuracy. Additionally, the controller’s onboard input/output capabilities allow for extensive automation, including limit switches, sensors, and auxiliary devices, enhancing both safety and functionality.

Another advantage of the PoKeys57CNCpro4x25 is its scalability. Whether managing a simple three-axis setup or a more complex four-axis or multi-spindle system, the controller adapts to the application’s needs. When paired with high-resolution stepper drivers like the PoStep25-256, it ensures that every microstep is executed accurately, translating into smoother motion and higher-quality finished parts. This combination of precision and flexibility makes the PoKeys57CNCpro4x25 a cornerstone in modern CNC operations.

Moreover, the PoKeys57CNCpro4x25 contributes to efficiency by enabling integration with diagnostic tools, such as PCB testers, and feedback systems that monitor machine performance. This connectivity ensures that any anomalies in electronic signals or mechanical motion can be detected early, preventing damage to the machine and maintaining consistent production quality. Its ability to bridge electronic control and mechanical execution exemplifies the level of sophistication expected in contemporary CNC setups.

In conclusion, the PoKeys57CNCpro4x25 is a powerful and versatile CNC controller that significantly enhances machine performance. By providing precise control over multiple axes, seamless integration with stepper drivers like the PoStep25-256, and advanced configurability, it empowers users to achieve highly accurate and efficient machining. For anyone seeking a reliable, high-performance controller for modern CNC applications, the PoKeys57CNCpro4x25 represents a top-tier solution.

What are CNC controllers with drivers and why are they crucial for automated machinery?

CNC controllers with drivers represent the backbone of modern automated machinery, combining control logic with the power to drive motors and actuators directly. Unlike standalone controllers that require separate stepper or servo drivers, integrated CNC controllers with drivers streamline the connection between software commands and mechanical execution. This integration ensures precise coordination of motion, reduces wiring complexity, and simplifies setup, making these systems especially attractive for both professional and hobbyist applications.

At their core, CNC controllers with drivers manage multiple axes of movement while coordinating speed, acceleration, and torque in real-time. By directly interfacing with stepper motors or servo systems, these controllers provide smooth, accurate motion, which is essential for tasks such as milling, engraving, 3D printing, or robotic assembly. When paired with high-resolution drivers like the PoStep25-256 or sophisticated controllers such as the PoKeys57CNCpro4x25, they enable extremely fine control over every microstep, ensuring that even the most intricate operations are executed with precision.

One of the key advantages of CNC controllers with drivers is their all-in-one convenience. Traditional setups often require separate components for the controller, stepper drivers, and communication interfaces, which can lead to compatibility issues or signal lag. Integrated systems reduce these challenges by combining the control logic and driving capability into a single unit. This not only simplifies installation but also improves reliability, as the hardware and firmware are designed to work together seamlessly. Manufacturers of CNC controllers with drivers often include advanced safety features, such as overcurrent protection, thermal monitoring, and emergency stops, which further enhance the robustness of the system.

Flexibility is another hallmark of modern CNC controllers with drivers. Many units support multiple communication protocols, allowing integration with software like Mach3, LinuxCNC, or proprietary control platforms. Users can adjust motion parameters, configure microstepping, and manage multiple axes simultaneously, making these systems suitable for both simple three-axis machines and more complex multi-axis setups. This adaptability ensures that CNC controllers with drivers can meet the demands of evolving production environments and increasingly intricate designs.

Moreover, CNC controllers with drivers play a vital role in ensuring system efficiency and precision. When combined with testing tools such as PCB testers, they provide feedback loops that confirm each component functions correctly before engaging in full-scale operations. This coordination between electronic verification and mechanical control minimizes errors, reduces material waste, and improves overall workflow. By integrating motion control and motor driving capabilities, CNC controllers with drivers form the foundation of high-performance, reliable, and precise automated machinery.

In summary, CNC controllers with drivers are essential for modern automation because they unify control and power in a single, efficient system. Their ability to manage multiple axes, deliver precise motion, and integrate with both software and peripheral tools makes them indispensable for anyone seeking reliable, accurate, and streamlined CNC operations. Whether in industrial settings or advanced hobbyist workshops, these systems provide the precision and flexibility necessary to meet today’s complex manufacturing challenges.

CNC Plasma Cutting Tech: PoKeys57CNCpro4x25 vs. PlasmaDiv vs. Integrated Drivers

IEPE, USB MSOs, and the Rise of Portable Oscilloscopes

Code, Cables, and Orchids: The Unlikely Tools Shaping Modern Creation

Conclusion

In the evolving landscape of electronics and CNC technology, having the right tools and components is essential for achieving precision, reliability, and efficiency. From the high-resolution stepper control offered by the PoStep25-256 to the diagnostic capabilities of PCB testers, each element plays a critical role in ensuring that machines and circuits operate flawlessly. Controllers like the PoKeys57CNCpro4x25 further elevate performance by providing advanced motion management, seamless integration with drivers, and extensive configurability. Meanwhile, comprehensive CNC controllers with drivers unify control and motor operation, streamlining complex workflows and reducing potential points of failure.

Together, these technologies form a cohesive ecosystem where electronics and mechanical motion work in harmony. They empower engineers, technicians, and hobbyists alike to push the boundaries of precision machining, intricate circuit design, and automated production. Understanding the unique strengths and applications of the PoStep25-256, PCB testers, the PoKeys57CNCpro4x25, and integrated CNC controllers with drivers allows users to select and combine components in ways that maximize performance and reliability.

Ultimately, whether in professional industrial settings or advanced personal workshops, leveraging these tools ensures that every project—from circuit boards to CNC-machined components—meets the highest standards of quality and efficiency. By embracing these innovations, users can confidently navigate the complexities of modern electronics and CNC systems, achieving results that are both precise and dependable.